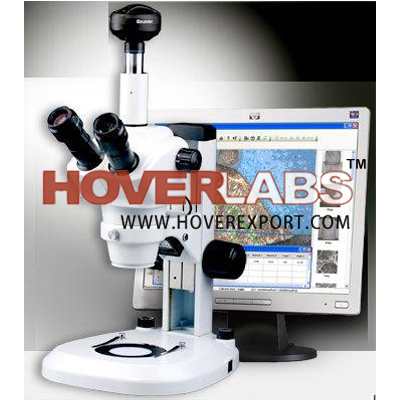

Weld Check Software For Metallurgical Lab

Model ME1126

Hoverlabs presents to the market to make workflow with great productivity and swift flow, with this effective designed software we can improve the usage in each needful measuring condition, which allows us measure neck, legs penetration. You will get accurate measurement through the software which improves the tolerance range in weld checking.

This software provides the knowledge about filet welding in which joins each other right angled to each other if the filet (Throat) is in centre the required measurement made from the root, the root penetrates from the joint to junction between exposed surface area of base metal and weld, measure could remain same amongst other sample. It make counting of phase, penetration of joint and area for Heat Affected Zone (HAZ)

To get better accurate and unaffected measurement make image zoom, to make it easier magnifier tool is provided. Zoom tool helps to see sample by increasing in size of whole sample in still seeing format.

This system is to analyse the characteristic of welded part in good and specific colour to help in operation.

MEASUREMENTS

Calibration - To measure Leg 1 and Leg 2, Penetration and throat measurements. - Can measure length, area, angle, diameter, radius, circumference in addition to weld penetration measurement - Can find mid-points, perpendiculars to lines, angle between lines - Ability to store drawings as a template for future use, thus ensuring maximum repeatability - Automatic measurements based on stored template, eliminating the need for manual measurements. - Automatic profile measurements. - Ability to create a master template for measurements for each type of component. - Ability to set expected value as well as tolerances at individual work level or at a master template level. - Automatic edge detection - Programmable (Automatic) measurement - Ability to stitch multiple reports together into a single report at component level if there are multiple welding on a component. - Integrated online Help. - Component level summary report, with images & measurements of each weld spots

REPORT - Reports in Excel or PDF format. - Report will have the measurement data as well as the image with drawings - Report on weld machine performance (Total, Pass, Fail) - Historical data analysis with performance graphs and deviation analysis reports

.jpg)